Coil-Service-Center.

Processing of strips and sheets.

We process customer requests in our processing center in Mannheim.

Here we can react quickly with a high and varied storage capacity and score points with customer-friendly service. With expertise and precise execution, our motivated processing team ensures that metals reach our customers in the desired requirements and quality >just-in-time<.

Our extensive machinery enables us to offer you a comprehensive package of services:

- Cross-cutting and slitting

- Intermediate storage

- Oiling

- Stamping

- Limited tolerances

- Wrapping

- Packaging

What we can do for you:

Sheets

Customizable and flexible according to your requirements.

Special formats / cuts

Fix lenghts sheets up to 12.000 mm

Fix - fix cuts, width and length cuts.

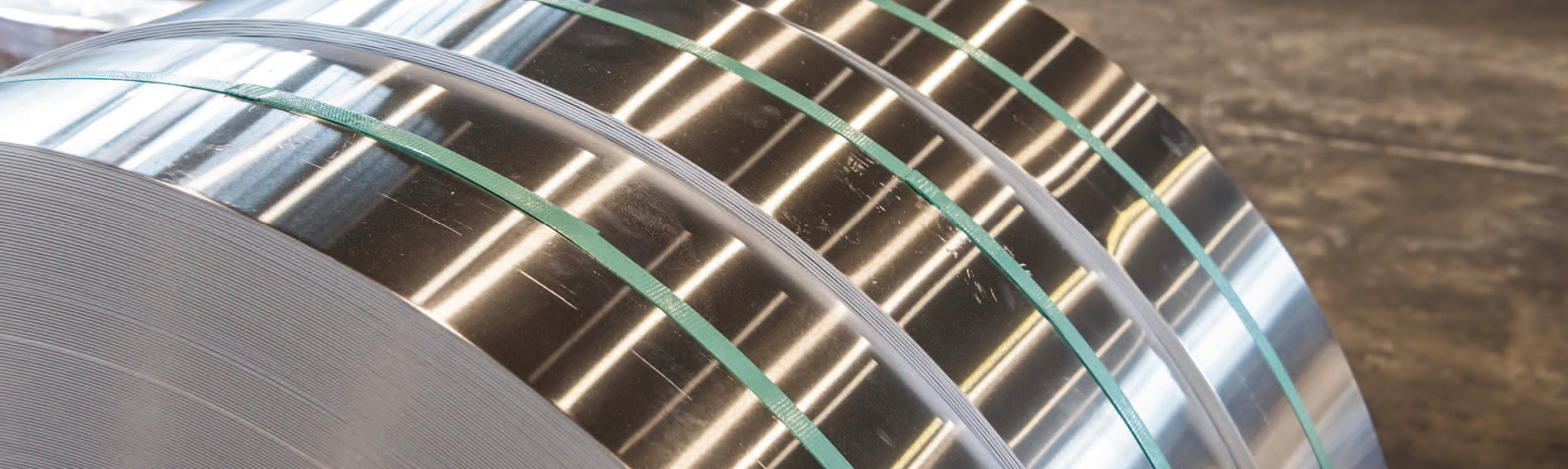

Slitted coils

Steel / stainless steel / aluminum straps

We cut customer-specific strips from steel, stainless steel and aluminum on the most modern cutting machines. The processing of refined material is also possible.

On request, we can cut your material fat-free or with a narrowed saber and width tolerances far below the DIN standard.

Processing of cross-cutting.

Our machinery includes two cut-to-length lines, one modern new acquired in 2022 and one completely overhauled in 2023.

Output of the machinery:

| Material strengths: | 0,50 - 4,0 m |

| Material widths: | 200 - 1.600 mm |

| Material lenght: | 300 - 10.000 mm |

| Coil: | max. 4,5 to. |

| Tolerances: | 1/2 EN |

| Stamping: | up/down |

| Foil: | up/down/double-sided |

| Paper: | yes |

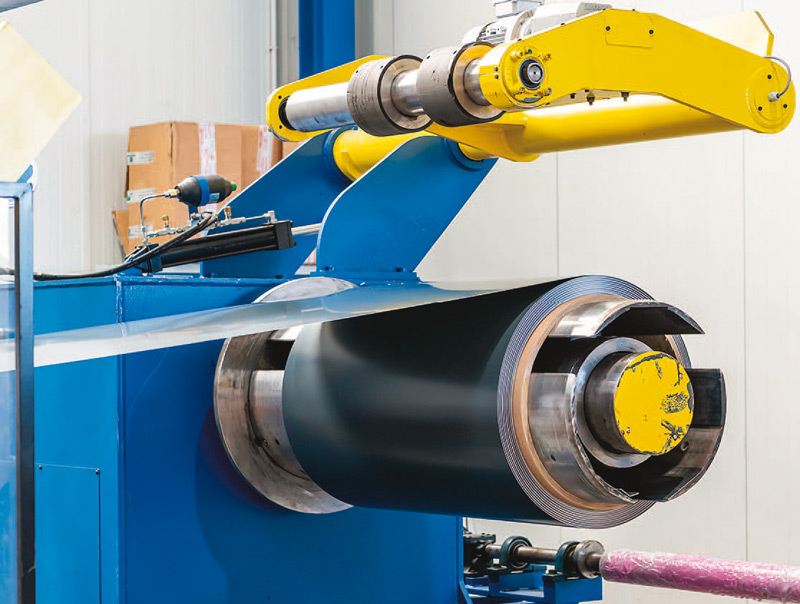

Processing slitting.

In the slitting area, we expanded our existing machinery to currently four slitting lines in 2023 with a modern new acquisition.

Output of the machinery:

| Material strengths: | 0,50 - 4,0 m |

| Material widths: | 20 - 1.600 mm |

| RID: | 400/500 mm |

| RAD: | max. 1600 mm |

| Coil: | max. 4,5 to. |

| Tolerances: | 1/2 EN |

| Foil: | p/down/double-sided |

| paper sleeve: | yes |

| Paper insert: | yes |

Small / large coils

Processing of coils and sheets

Decoiling | Rewinding tapes onto other tape weights (small coils)

Subcontracting

We offer an all-round package consisting of incoming goods, intermediate storage, processing, packaging, transport, just-in-time.

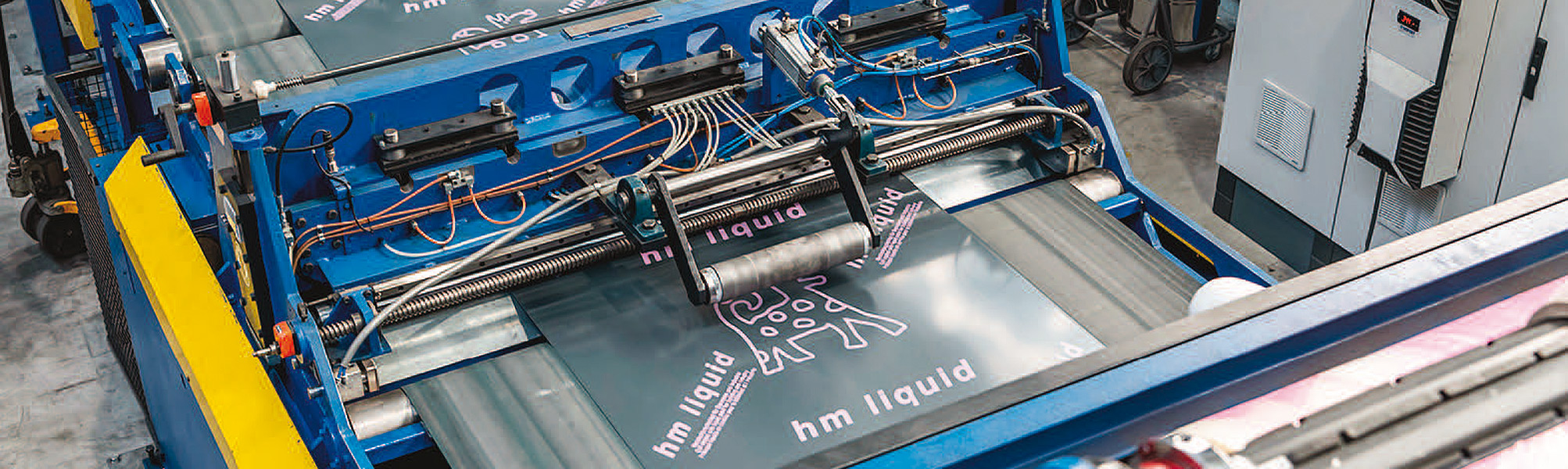

Foliation

We coat metal sheets and plates on one and both sides on our foiling systems.

We use various standard or laser foils depending on the customer's requirements.

| Film type | Manufacturer | Label | Thickness | Application examples |

|---|---|---|---|---|

| PF 561 C / 80 (Orientation) |

Polifilm | Red arrows on grey-white surface UV-resistant 12 months | 80 μm | All mill-finished aluminium surfaces, anodized painted, coils, sheets |

| PF 84 C (Laserfoil) |

Polifilm | Laser marking in blue on black surface | 100 μm | For all surface qualities Use on CO2 and solid-state lasers |

| PF 22 | PF | Blue transparent | 50 μm | Bedingt UV-beständig, Alu, Edelstahl |

| A 15 | Coefilm | Limited UV resistance aluminium, stainless steel | 50 μm | UV resistance |

- UV resistance according to Western European climate = 300 h QUV test.

- When removing protection films, the processing temperature should be >10°C - <40°C!

- Other film types and other film manufacturers are available on request